Dikte-afsetting-uniformiteit

Inleiding

Magnetron sputtering coating word wyd toegepas in die groot area afsetting, en dun film dikte eenvormigheid, afsetting verhouding, benutting verhouding van teiken materiaal en ander probleme in coating industrie word groot aandag gegee.

Of dit nou 'n halfgeleierskyfie met 'n beskermende dun film bedek of 'n anti-reflektiewe laag op 'n brillens aanbring, prosesingenieurs moet sekere dikte-spesifikasies bereik om aan prestasievereistes te voldoen. Net so belangrik as die filmdikte self is die eenvormigheid van die dikte.

Faktore wat neerslagprestasie bepaal

Afsetting, 'n proses wat gebruik word om dun lae materiaal (of film) op 'n substraat neer te sit, is 'n algemene praktyk in nywerhede soos halfgeleiers en nanotegnologie. Dunfilmneerlegging kan bereik word met 'n verskeidenheid tegnologieë wat films kan verskaf wat wissel van isolators tot halfgeleiers tot metale. Die rolprente kan rolle ewe uiteenlopend dien wat wissel van tussenlaagdiëlektrika tot onderlinge verbindings.

Buigsaamheid

Buigsaamheid, die reeks vermoëns wat 'n stelsel het, kan 'n belangrike faktor wees om 'n besluit te neem oor watter tipe afsettingstelsel om te verkry. Dit is meer waar vir R&D-omgewings eerder as industriële toepassings waar spesifieke oplossings dikwels verkies word. Begrip van die materiale wat neergelê kan word, substraatgroottes, temperatuurreekse, ioonvloed, afsettingstempo's, frekwensies, eindpunt en drukbedryfstelsel is slegs enkele van die oorwegings. Buigsaamheid is ook 'n stelselkwaliteit wat beplanning vir die toekoms moontlik maak. In R&D verander prioriteite en dit is nuttig om 'n stelsel te hê wat daardie veranderinge kan hanteer. Bo-op hierdie oorweging is begroting. Afhangende van die tipe tegnologie-opsies, kan stelsels aansienlik verskil in prys.

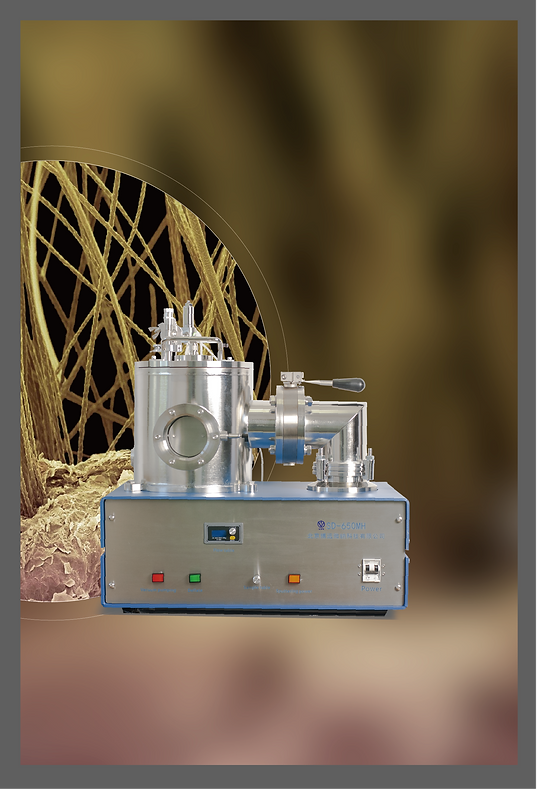

Toetsverslag vir VPI-bedekkingsmodel:SD-900M

Linkerkantfoto

Results & Conclusions

Shows the result of the X-ray diffraction of the Ga2O3 films growth with various O2 flow rates. The diffraction peaks located at 29.7°, 37.6°, and 58.4° originate from the 400, 402, and 603 of the β-Ga2O3, respectively. For the sample without the O2 flow rate, 400, 402, and 603 of the β-Ga2O3 diffraction peak coexisted; this suggests that the sample was polycrystalline. With the O2 flow rate increased from 0 to 4 sccm, the diffraction peak intensity of the 400 β-Ga2O3 decreased, while the intensity of both the 402 and 603 of β-Ga2O3 diffraction peak increased. Both of these two diffractions belong to the 201 plane family of the monoclinic Ga2O3. The above result illustrates that highly 201-textured β-Ga2O3 samples have been prepared and the orientation of crystal is gradually enhanced when oxygen flow increased. Furthermore, the full width at half maximum (FWHM) values of the 402 β-Ga2O3 peaks are 1.00°, 1.10°, 1.06°, and 0.96° for samples with the O2 flow rate increased from 0 to 4 sccm, respectively. The FWHM value is dependent on the O2 flow rate, and the results suggest a higher O2 flow rate results in improved crystal quality. The minimal FWHM is obtained at 4 sccm of the O2 flow rate, which means the grain size is the largest. The combined results of the XRD peak intensity and the FWHM value of the samples show that higher O2 flow rates lead to better quality.

In summary, in terms of the effect of oxygen flow on the structure, optical l properties of the Ga2O3 films have been investigated by XRD, EDX, AFM, transmission spectra, and PL spectra. With the increase in the oxygen flow rate, both the crystal quality and luminescence intensity of the sample first decreased and then enhanced. All these observations suggested that the reduction in the oxygen defect density is responsible for the improvement in the crystal quality and emission intensity of the material, however, there have been no reports about O2 flow rate on the properties of the Ga2O3 growth by RF magnetron sputtering. Our results were similar to those obtained by other techniques and the specific control of various experimental operating parameters. Vu found that the performance of β-Ga2O3-based photodetectors with a higher oxygen partial are better than those prepared at lower oxygen pressures. Wang et al. studied the influence of oxygen flow ratio on the performance of Sn-doped Ga2O3 films by RF magnetron sputtering; they found the sample with higher oxygen flow ratio displays an enhanced performance. Shen’s study revealed oxygen annealing will enhance the performance of β-Ga2O3 solar-blind photodetectors grown by ion-cutting process. Our results demonstrated that high-quality gallium oxide materials can be obtained by adjusting the oxygen flow rate.